How to define motion in CENOS

Movement is an important part for a lot of induction heating systems, as translational or rotational movement helps to heat/harden the specific part uniformly and efficiently. To accurately simulate such processes, you need to take into account the respective types and speeds of the movement present in your system.

In this article we are going to take a look at how movement can be defined in CENOS, what are the requirements for movement and what limitations are currently present with such setup.

Motion in CENOS

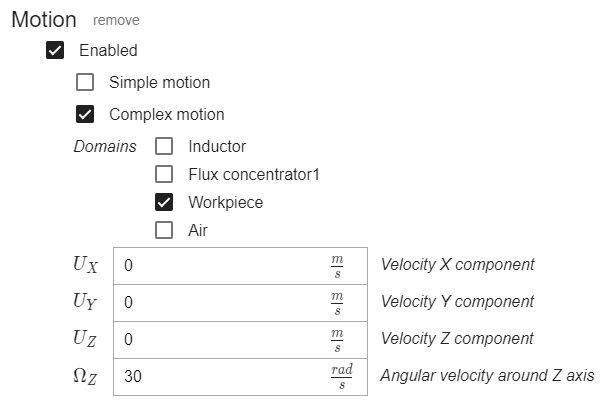

CENOS supports both translational (scanning) and rotational (single-shot) movement. To define motion in your simulation, go to Motion tab in PHYSICS section and click CREATE NEW MOTION.

Select the type of motion, which part you want to move, in which direction and with what speed, and CENOS will do the rest!

Types of Motion

When defining Motion, you will notice that there are 2 options to choose from - Simple Motion and Complex Motion.

Simple Motion

This option allows you to simulate motion for axially symmetrical or continuous workpieces.

Some examples would include:

As you can see, Simple Motion can be applied to systems where it can be assumed that the geometry is not moving. This can be very useful for completely symmetrical part rotation or modelling of continuous feed of material through the system.

Use Simple Motion if it is possible, as it calculates a lot faster than Complex Motion.

Complex Motion

If Simple Motion is not applicable to your case, you need to use Complex Motion.

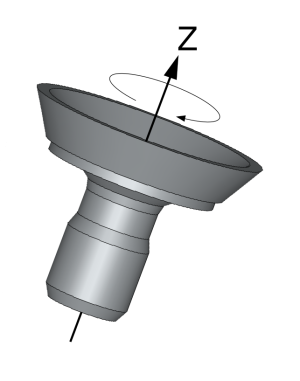

For parts with splines, teeth, holes, gaps and other kinds on unsymmetrical details an actual motion needs to be simulated. Complex Motion enables you to move the respective parts in your system.

Make sure that the calculation time step is small enough to capture the rotation smoothly! No more than 30 deg turn in one time step!

Limitations

Even though the Movement definition is easy to use, there are still some things to keep in mind when defining movement in CENOS.

Rotation axis

Rotation currently is limited only around the Z axis, so be sure that your rotational system is positioned around the Z axis!